In 2015, Wagman expanded its service offerings to include Grooving & Grinding. These are proven methods that improve road and bridge deck imperfections, create a smoother ride and provide a variety of safety features from better traction to rumble strips.

The services can be used together or separately depending on the project. Grinding is a cost-effective method that removes imperfections and creates a smoother and safer riding surface. The finished surface is similar to a corduroy texture. As grinding progresses, slurry is vacuumed and pumped into a tanker.

The services can be used together or separately depending on the project. Grinding is a cost-effective method that removes imperfections and creates a smoother and safer riding surface. The finished surface is similar to a corduroy texture. As grinding progresses, slurry is vacuumed and pumped into a tanker.

Grinding is often utilized for correction in longitudinal directions on asphalt, concrete pavements and bridge decks.

Grooving involves multiple diamond blades moving in a transverse direction on a bridge deck to produce a mechanically tined surface for skid resistance and traction.

Grooving & Grinding are ideal for:

- Bridge decks

- Airport runways

- Taxiways & aprons

- Parking decks

- Sawed-in rumble strips (4 inches wide and 1/2 inch deep)

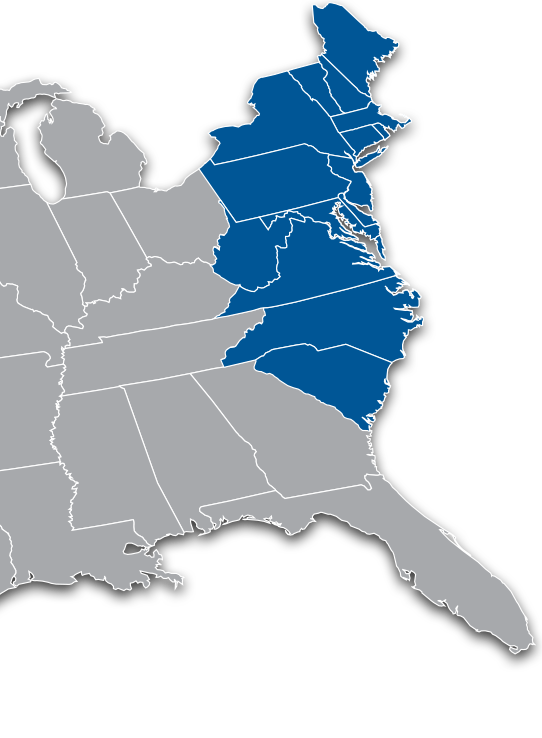

Since 2015, Wagman has completed Grooving & Grinding projects in 15 states and the District of Columbia.

Wagman is using a state-of-the-art PC 4500 Highway Grinder. The compact equipment and skilled personnel allow for easy mobility and quick response time to projects along the East Coast.

Grooving and Grinding Projects

I-95 Deck Rehabilitation and Joint Modification

View This Project

Delaware Water Gap

View This Project